Reducing Energy Wastage

Aero Truck’s patented active aerodynamic system is designed to reduce energy wastage by reducing drag on heavy duty buses and trucks, thereby reducing energy consumption and improving range. The technology is designed to work with all types of motive power including internal combustion engine, hybrid, fuel cell and battery electric systems.

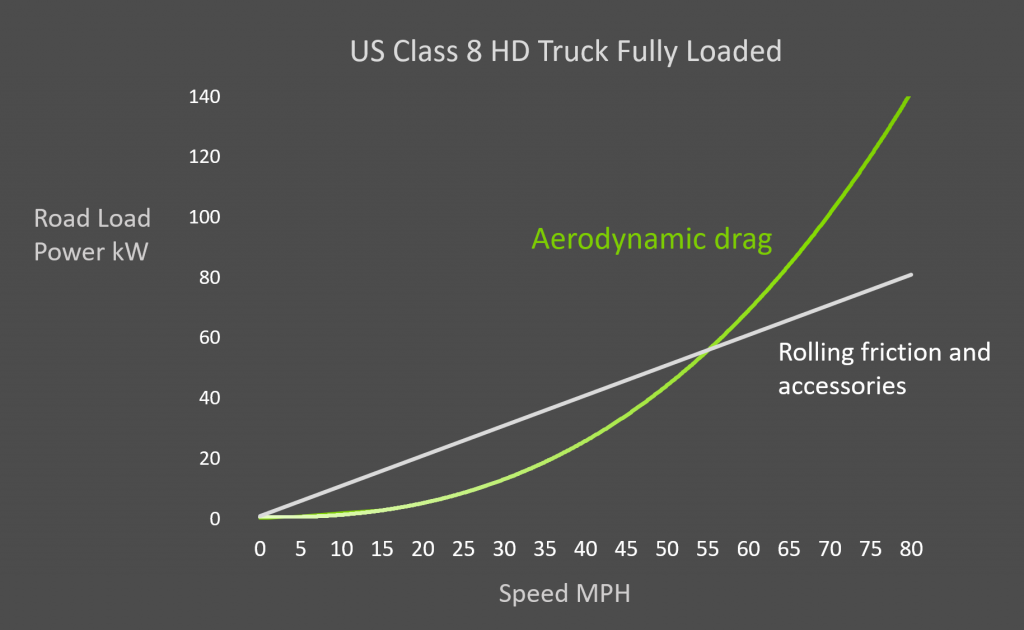

During driving, energy is wasted overcoming mechanical friction and rolling resistance of the tyres on the road surface as well as wind resistance. The contribution of wind resistance to energy wastage increases strongly with speed, such that at highway speeds wind resistance on trucks and buses often predominates.

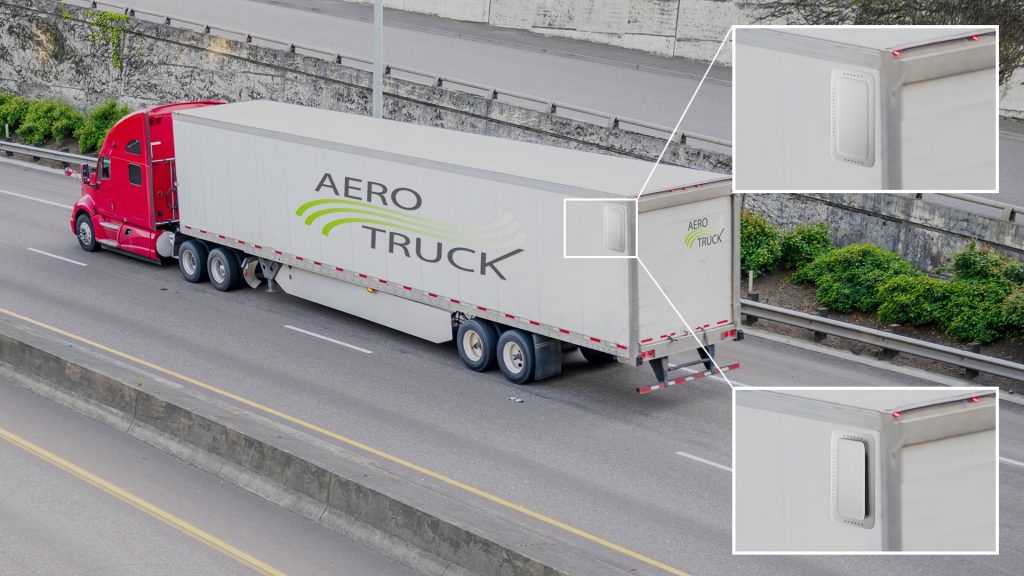

Rear mounted side flaps

Whilst existing passive aerodynamic flaps can reduce drag on tractor units and trailers, significant further benefits can be achieved by using dynamic flap systems which can interact both actively and adaptively with airflow eddies as they form at the rear surfaces of trailers. Our patented system is designed to disrupt air flow eddy formation and the break off of Strouhal eddies, by monitoring the dynamic pressure signal at the back of the truck and adjusting one or more airflow flaps accordingly. This in turn increases the pressure at the back of the truck and contributes to reducing aerodynamic drag.

The system is packaged to provide no or minimal intrusion into the load space of trailers and can be retrofitted to existing trailers as well as designed into new trailers. The level of benefits will depend on the duty cycle of the vehicle. At highway speeds our current demonstrator is repeatably delivering fuel consumption reductions of up to 15% in fuel economy and range.

The system has been designed such that the cost of fitting can be recovered typically within 12 months for long distance haulage.

Top mounted flap

Top mounted flap